Same Game, New Ball: The NBA Standard For their Basketball is Changing

Basketball has standards. Standards that continue across all NBA games, ensuring each player can have an equal and fair experience on the court.

The game ball has standards too. It must always bounce the same, grip the same, and always be made by Wilson. These characteristics are routines when using the classic materials of the rubber bladder and leather coating.

Since there is already a standard, recreating the ball with different materials poses many difficulties. But with leather and rubber being unsustainable to source, Wilson has been working on a new basketball: and they have almost done it.

A classic basketball going into a basket. (Photo by Trevor Williams/Getty Images)

The Wilson Airless Prototype is an airless black basketball, that is see-through. The exterior of the ball is made of eight panel-like lobes filled with hexagonal holes, meant to mimic the classic ball. However, the ball is a singular structure.

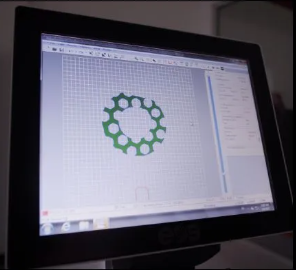

It can be created as one entity through a 3D-printing process that uses ‘research-grade materials.’ Built from the bottom up, it is drawn by a machine.

The Wilson Airless Prototype being 3D printed as one structure, from the ground-up. (Photo retrieved from Wilson)

Figuring out the right combination of additives for the ball took several years and a skilled team. These materials are not listed online, likely as a trade secret.

But this new ball nearly meets all the standards of the normal game ball: from weight, to size, to bounce, to rebound.

This ball has even been used in NBA competitions, but not the conventional kind.

A cinematic shot of the Wilson Airless Prototype sitting in a pile of powder that is used in the printing process. (Photo retrieved from Wilson)

Its debut was in the NBA All-Star Dunk Competition, and it entered the court in a glass case. Kenyon Martin Jr. #6 of the Houston Rockets removed it from its abode, where he let judges handle the ball as a test.

Martin took a few attempts at his trick dunk with the new ball. The ball was eventually tossed up against the backboard, into his hands perfectly.

He thrust the ball down between his knees as he rotated 180 degrees in the air. Then, he slams the airless ball behind his head and into the net for the dunk.

Kenyon Martin Jr. #6 of the Houston Rockets holding the Wilson Airless Prototype in front of him. (Photo retrieved from Wilson)

This was the first instance of the Wilson Airless Prototype bein used in an official NBA setting, but likely will not be the last.

As the world is forced into sustainability through the hindering effects of climate change, innovations like this will be brought into all aspects of sports.

Cow leather used in current balls takes vast amounts of resources to produce, as well as hand-stitched labor to make the perfect Wilson balls we know today.

Synthetic balls are the next step in making the NBA more sustainable. We will continue to see new changes to the sport in the coming years to meet climate goals.

The next steps may be sustainably sourced jerseys or even biodegradable shoes. Whatever is next – basketball will continue to change to reflect the society that loves to play and watch the sport.